02 Aug 7 Surprising ways How Supply Chain Benefits our society – In Terms of Business

Management aids in the achievement of group goals by arranging production variables, assembling and organizing resources, and efficiently integrating resources to fulfill objectives. It helps to organize the process towards achieving a particular target.

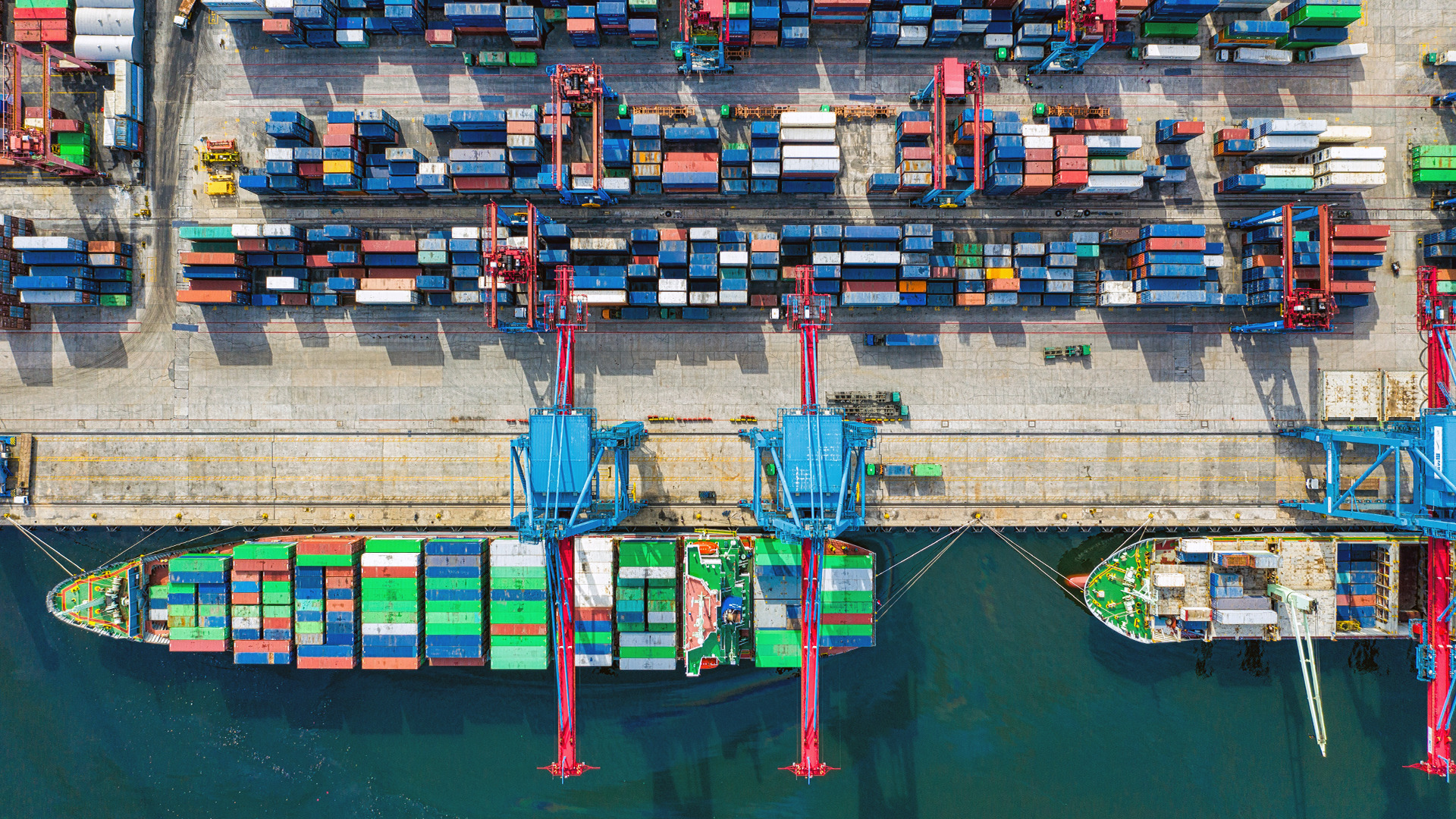

Similarly, Supply Chain Management is concerned with how companies transform raw materials into completed goods and then transport and distribute them to customers. Supply chains connect businesses to their suppliers, allowing them to manufacture and deliver goods and services.

Benefits of Supply Chain to our Society:

Issues of sustainability will have an impact on the environment, society, and economy. In the case of large-scale firms, supply chains provide fateful benefits in achieving long-term viability. The following are a few of the advantages:

Better Collaboration:

Information flow is a major issue for businesses. Integrated software solutions eliminate bottlenecks and enable seamless information interchange, giving you a complete picture of the supply chain from beginning to end. Thanks to better data access, supply chain leaders now have the knowledge they need in context to make more educated decisions.

Improved flow of Product and material:

The time-to-consumer is an important metric for measuring product flow efficiency. The less time it takes for goods to reach the end customer, the more efficient the product flow. However, there are numerous other factors to consider including the quality of the resources or items that reach customers, the supply and demand balance, shipment alternatives, and inventory levels.

Reduced Environmental Impact:

There is a frequent notion that decreasing a company’s environmental impact is expensive. But in reality, it has the potential to save a lot of money. You may instantly see results by decreasing waste and improving the efficiency of buildings, cars, and machines. Supply chain assists in managing the needed circumstances to lessen environmental impact.

No More Process Delays:

One of the advantages of the supply chain is that delays in processes may be reduced through communication. This will lessen any late shipments from suppliers, logistical mistakes in the distribution channels, and delays on the manufacturing lines because everyone is mindful of what they’re performing and also what others are doing.

Potential for new Partnerships:

This one might be a little more subtle. A company having a long-term supply chain is also appealing to other companies wishing to partner with it. Your environmental credentials will very certainly coincide with the values of another company. As a result, potential partnership opportunities arise.

Enhanced Risk Reduction:

Large-scale and detailed supply chain data analysis may identify possible hazards, enabling businesses to set up backup plans to quickly react to unforeseen events. Companies may avoid bad effects by being proactive rather than responding to supply chain interruptions, quality control problems, or other difficulties as they occur. Understanding risks also aids businesses in running more efficiently. For instance, 87 percent of businesses think that if they had a better awareness of the dangers in their supply chains, they could cut inventories by 22 percent.

Improved quality control:

Improved quality control benefits companies that have more control over not only their direct suppliers but also their suppliers’ suppliers. Using common minimum quality criteria, for example, allows direct providers to find and engage with secondary suppliers who match those criteria. Supply chain management monitors key performance indicators including:

- On-time delivery

- Final product quality

- Time for complaint resolution

- Findings from supplier quality assessments

- Scrap rates rework and similar issues at suppliers

Keeping up with the demand:

Complications might arise as a result of several issues related to unexpected retailers’ demand for products. Supply chain leaders who have access to real-time, precise, and integrated data may better estimate the product demand and respond quickly to changing market conditions, avoiding problems.

Greater Efficiency:

Real-time information on raw material availability and production delays enable businesses to put backup plans in place, such as procuring resources from a second supplier, preventing additional delays. Without real-time data, businesses sometimes lack the time to start plan B, leading to problems like out-of-stock inventories or delayed shipments to final customers. Putting into practice intelligent automation solutions also increases effectiveness.

Lowers the cost of doing business:

This is accomplished by lowering purchasing and manufacturing costs. For example, if you operate a grocery shop and buy tomatoes directly from the farmer, you avoid the cost of having a third party purchase fruit for you. Buying directly from the source saves you money and allows you to get the goods on your shelves faster.

Conclusion

Companies will be able to handle and adapt to ever-increasing complexities if they have effective supply chain management in place, which comprises strategies and best practices for integrating and coordinating all the functions, activities, transactions, and people in the complete value chain.

No Comments